Product Display

Custom Cast Polyurethane Couplings& Urethane Couplings

PEPSEN specializes in producing a wide range of polyurethane flexible couplings, encompassing diverse designs, configurations, and material compositions. Our meticulous approach to coupling development takes into comprehensive account the full spectrum of operational parameters and performance requirements unique to your application. By thoroughly understanding and addressing these variables, we deliver polyurethane flexible couplings that are precisely tailored to meet the multifaceted needs of your machinery, enhancing overall system performance, reliability, and longevity.

The Factors We Consider When We design

• Torsional Stiffness: Ensuring the coupling maintains optimal balance between rigidity for efficient torque transfer and flexibility for effective shock absorption and vibration damping.

• Horsepower Capacity: Designing couplings with the strength and durability to withstand the specified horsepower output, ensuring reliable power transmission without premature failure.

• Shaft Misalignment Tolerance: Tailoring the coupling's geometry and flexibility to accommodate and compensate for angular, parallel, and axial misalignments between shafts, minimizing stress on connected components and extending equipment life.

• Backlash Control: Implementing design features that minimize or eliminate backlash, enhancing precision and positional accuracy in applications where it is critical.

• Rotational Velocity: Ensuring the coupling's material and design can withstand the intended rotational speeds without compromising performance or longevity.

How Does Polyurethane Coupling Work?

Fundamentally, urethane couplings serve to securely unite two shafts, maintaining their operational connection while facilitating the seamless transfer of power. Crucially, they accommodate inevitable shaft misalignments, enabling the cohesive functioning of paired rotating machinery.

Couplings find widespread application in connecting drive shafts to driven shafts, motors to pumps, gearboxes to driven machinery, motors to gearboxes, and even internal combustion engine flywheels to a diverse array of equipment, such as pumps, transmissions, blowers, and more.

Different Kinds Of Polyurethane Couplings

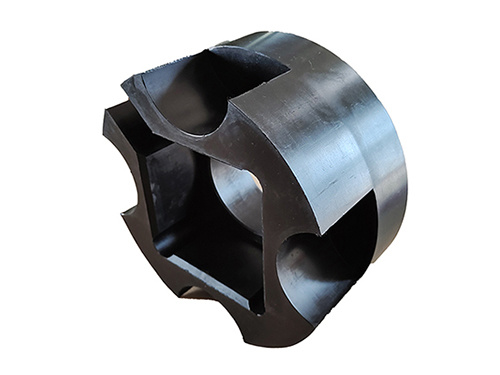

1. Rigid-Flexible Couplings (RF): These couplings combine a rigid metal hub on each end with a flexible polyurethane insert or sleeve in the middle.

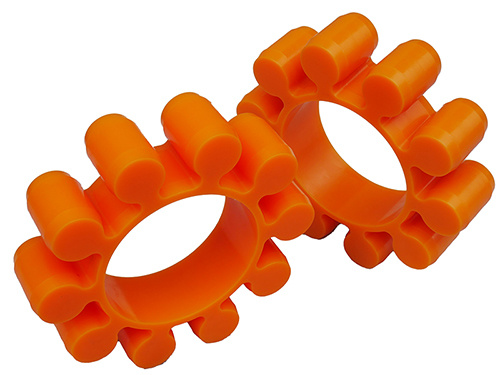

2. Spacer-Type Couplings (ST): Also known as "membrane" or "spider" couplings, these consist of a polyurethane elastomeric element sandwiched between two flanged hubs.

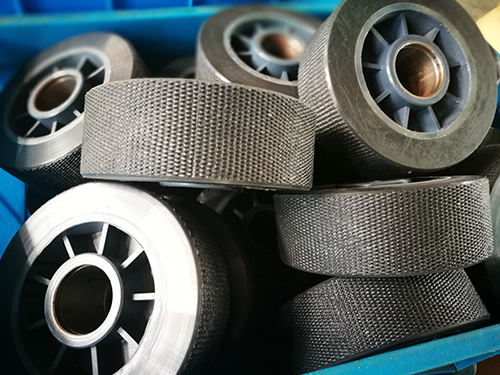

3. Disc-Style Couplings (DS): Consisting of multiple polyurethane discs alternating with metal hubs or center members, disc-style couplings provide high torsional stiffness, excellent misalignment compensation, and low backlash.

4. Beam-Type Couplings (BT): These couplings feature a series of interlocking metal beams with polyurethane inserts or coatings.

5. Bellows Couplings (BC): Although not exclusively made of polyurethane, bellows couplings often incorporate polyurethane elements in their design.

6. Laminated Elastomeric Couplings (LEC): LECs are composed of multiple layers of alternating metal and polyurethane, forming a flexible yet strong coupling that can withstand high torque loads and accommodate significant misalignments.

7. Customized or Specialty Couplings: PEPSEN, as a manufacturer specializing in polyurethane couplings, can develop bespoke solutions tailored to unique application requirements. These may involve incorporating specific geometries, materials, or reinforcement structures to address challenges such as extreme misalignments, high torque, or unconventional mounting configurations.

previous

previous

Product inquiry