Product Display

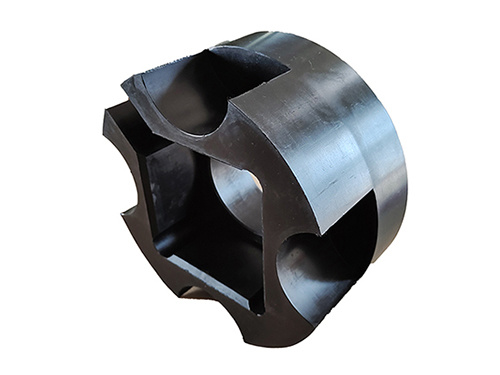

Solid Polyurethane Rubber Ball-Urethane Ball

Solid Polyurethane Rubber Ball-Urethane Ball Shanghai Pepsen has been developing and manufacturing custom cast molded solid polyurethane balls for different applications. Solid polyurethane balls are versatile components that find application in numerous industries and functions due to their unique combination of properties such as durability, elasticity, and resistance to wear and tear. They are mainly used as check valves ball and 70% rebound urethane balls used on balance board for fitness, special bearings, and pneumatic pumps.

Polyurethane Ball for check Valve

Polyurethane balls, when utilized as sealing elements in check valves, showcase an array of advantageous characteristics that make them a preferred choice in many fluid control applications. Check valves are essential components that allow unidirectional flow, automatically preventing backflow when the upstream pressure drops. Integrating polyurethane balls into these valves amplifies their performance and longevity.

Polyurethane, being a synthetic polymer, possesses a unique blend of properties that are especially valuable in valve applications. Firstly, it exhibits extraordinary resistance to wear and tear, making it ideal for the repetitive movement and potential contact with abrasive fluids common in check valve operations. The material's durability ensures that the ball remains dimensionally stable and maintains a tight seal over time, reducing the likelihood of leaks and system failures.

Its inherent flexibility and resilience mean that polyurethane balls can accommodate minor misalignments in valve seats, enhancing the valve's sealing performance. Moreover, polyurethane's low compression set property ensures the ball returns to its original shape quickly after being subjected to compressive forces, further reinforcing the valve's sealing integrity.

Polyurethane balls can be custom molded to precise dimensions, ensuring a perfect fit for various check valve sizes and configurations. They can also be formulated with specific hardness levels (durometers) to cater to different pressures and operating conditions, ranging from soft and pliable for quieter operation to hard and rigid for high-pressure applications.

Urethane Balls Used On Balance Board for Fitness

Urethane balls play a pivotal role in enhancing the functionality and durability of balance boards used for fitness purposes. Balance boards are innovative exercise tools designed to improve core strength, coordination, and proprioception—our body's awareness of its position and movement in space. Integrating urethane balls into these boards takes their performance and user experience to a new level.

In the context of balance boards, urethane balls serve as pivot points or fulcrums, providing a dynamic and responsive surface that challenges users to engage their stabilizing muscles continually. Unlike traditional materials like rubber or plastic, urethane offers a higher degree of shock absorption and wear resistance, which translates to a quieter, smoother, and more controlled workout session.

Moreover, urethane balls offer a significant advantage in terms of grip and traction. Their non-slip texture prevents slippage during workouts, ensuring user safety and stability. The material is also able to endure the friction caused by continuous rolling or pivoting actions without showing signs of degradation, making it a reliable choice for long-term use in fitness equipment.

Customizability is another key attribute of urethane balls used in balance boards. They can be manufactured in various sizes and hardness levels (durometers), enabling fitness equipment manufacturers to tailor the difficulty and feel of the balance board to cater to different fitness levels and training objectives. Softer urethane balls might provide a gentler, more forgiving platform for beginners, while harder ones could challenge experienced users seeking a more intense workout.

Other Applications Of Solid Urethane Ball

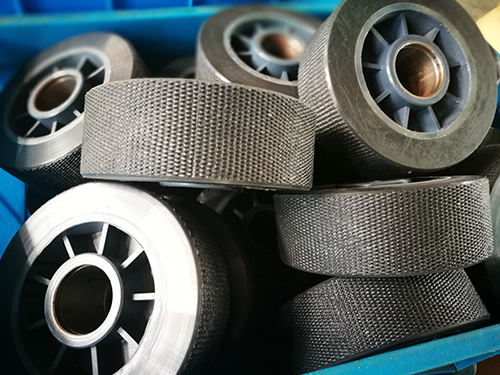

Ball Bearings: Solid polyurethane balls are used in special types of bearings where high wear resistance, low friction, and noise reduction are paramount. They are ideal for environments where metal or ceramic balls might suffer from corrosion or excessive noise generation.

Conveyor Systems: As roller and guide components in conveyor systems, solid polyurethane balls minimize noise, vibration, and material damage. They are particularly useful in food processing and packaging lines due to their non-marking and FDA compliant properties.

Roller Skates and Skateboards: High-density solid polyurethane balls are used as wheel cores or bushings, providing a smooth ride, excellent shock absorption, and minimal maintenance.

Mechanical Seals: In pumps and other rotating machinery, solid polyurethane balls can serve as backup or emergency seals, thanks to their ability to conform to irregularities and their resistance to swelling or shrinkage.

Automotive Applications: From door hinges to window regulators, solid polyurethane balls can be used as silent, lubrication-free components that dampen vibrations and enhance the longevity of moving parts.

Product inquiry