URETHANE LINER FOR POLYSILICON INDUSTRY

URETHANE LINER FOR POLYSILICON INDUSTRY

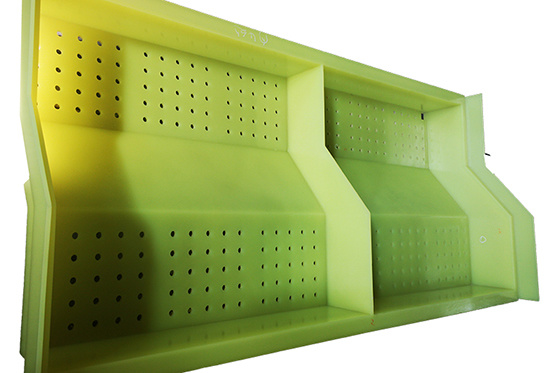

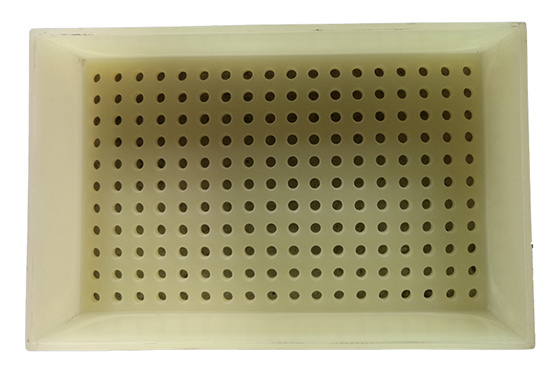

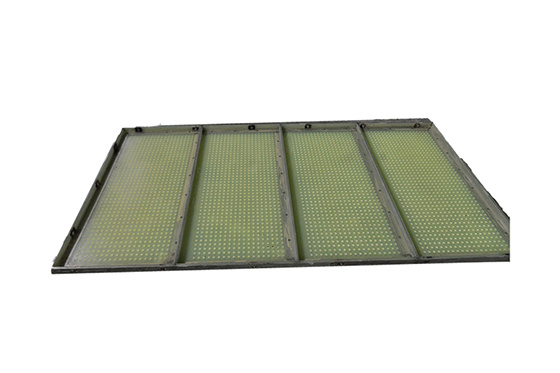

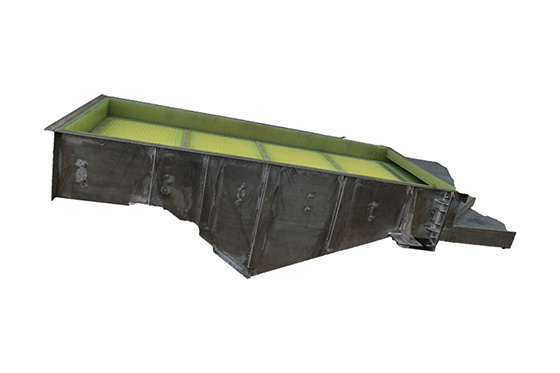

The urethane liner for silicon rod transfer vehicle is designed by PEPSEN specifically for polysilicon industry. It can fully protect the silicon rod from contact with the metal part of the transfer vehicle. It has the advantages of collision resistance, puncture resistance, no chipping, and damage resistance; it is also easy to install, clean and replace. In the production process, polysilicon production enterprises need to avoid the contamination of silicon materials by contact objects as much as possible in the entire production and circulation links, especially the contamination of silicon materials by metal components, due to the stringent requirements on the purity of silicon materials. This requires the isolation and protection of metal tools, production facilities, and transfer equipment involved in the entire production and flow links of silicon materials. Traditional protective materials are mostly made of plastic materials such as PVC, tetrafluoroethylene, PE and ABS. During use, it is easy to produce problems such as plastic fragility, slag falling, non-wear resistance, non-durability, and defects in the appearance and structure of protective products, which plague production and product quality. The application of suitable types of high-quality polyurethane elastomer material products in this field has greatly improved the above defects.

Typical characteristics of polyurethane elastomers

• High wear resistance: polyurethane elastomers are more wear-resistant than other known polymer materials. Wear resistance means that the generation of debris is reduced, pollution is reduced, and the service life and cost-effectiveness of the product are also improved.

•High strength: The excellent tensile and tear strength and impact resistance of polyurethane elastomers enable the material to be competent for more difficult tasks, such as high-frequency crushing table protective sleeves.

• Outstanding elongation at break: The elongation at break of polyurethane elastomers is usually 300-800% or even greater, which means that even if there is a large local deformation during extreme use, the polyurethane will not easily break the material, reducing the undesirable phenomena such as the slag falling of the material.

• Good elasticity and recovery: polyurethane elastomers have excellent elasticity and recovery. In contact with extremely hard and sharp polysilicon materials, they can still self-heal even if they are repeatedly punctured, and are not prone to material damage, maintaining a long-lasting protective function.

• Convenient molding process: The flexible process of cast polyurethane elastomers makes large-sized and complex-shaped workpieces possible. Very suitable for the personalized needs of different manufacturers and different products.

Advantages of Shanghai Pepsen in serving polysilicon enterprises

• Our professional team has 20 years of experience in the research and development and production of polyurethane elastomers, and has a high reputation in the domestic polyurethane elastomer industry.

• We are a company with a certain scale and a long history in this industry, which has achieved management standards, environmental protection standards, safety standards, ISO quality system, and is a qualified supplier of some confidential products for an important national department.

• We were invited to conduct in-depth research, design and development for domestic well-known polysilicon companies, and successfully applied polyurethane elastomers in protective products for polysilicon production enterprises, and received good praise; We are the earliest domestic company in this field to successfully serve polysilicon production enterprises with polyurethane.

• We not only understand polyurethane, but we also have a deep understanding of the production links and protection requirements of polysilicon enterprises. At present, the companies we serve have zero complaints about our products and services.