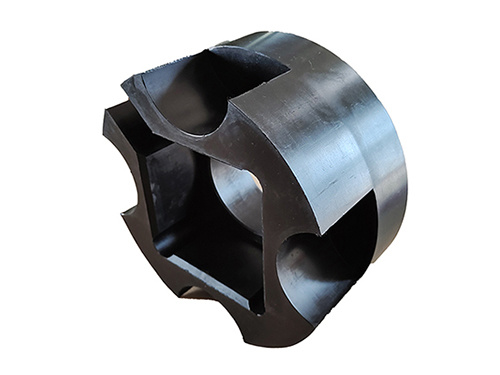

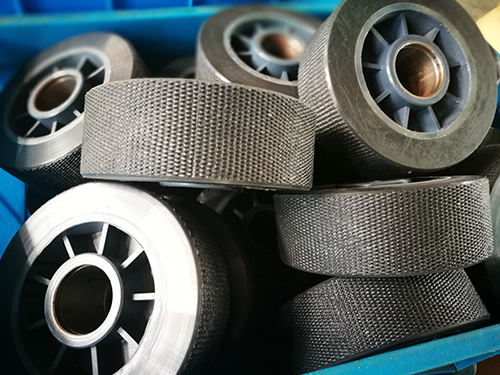

Product Display

Polyurethane Snow Plow Blades - Urethane Snow Plow Cutting Edges

Shanghai Pepsen has been manufacturing snow plow blades using high performance polyurethane/urethane for snow removal industry. Specifically designed to withstand the harshest conditions, these blades utilize a uniquely formulated polyurethane compound that has been rigorously tested on-site, proving capable of enduring temperatures as low as -30 degrees Celsius. They notably outperform traditional steel, rubber, plastic substitutes, as well as competing polyurethane products in terms of longevity.

Where are snow plow blades used?

For diverse commercial snow clearing tasks, these blades are applicable across a variety of settings, such as airports where rapid clearance is essential, thoroughfares requiring efficient snow removal, pedestrian walkways, and expansive parking areas. They integrate seamlessly with larger-scale commercial plowing machinery, including heavy-duty trucks and specialized large commercial vehicles.

On the residential front, these blades equally shine in smaller-scale snow removal operations, tackling driveways and sidewalk clearing with ease. They are compatible with a variety of smaller vehicles and equipment, such as All-Terrain Vehicles (ATVs), Utility Task Vehicles (UTVs), agricultural tractors, and light-duty trucks, ensuring suitability for homeowners and small-scale contractors alike.

Benefits of Polyurethane Snow Plow Blades

•The wear resistance is five times that of rubber

•Noise abatement

•Easy Installation

•Holes can either be molded or drilled

•Customized hardness, dimensions and color

•Can be special formulated to add abrasion resistance.

Procedure for Replacing the Cutting Edge on a Snow Plow

Disassembling the Old Cutting Edge Begin by carefully detaching the worn-out cutting edge from the snow plow. Unscrew and remove all the bolts securing the old blade to the plow structure, ensuring safe storage of the fasteners for reuse. Once all bolts are extracted, gently lift away the old blade.

Transferring the Bolt Pattern Place the retired blade atop the new one, making certain they align perfectly. Utilize a marker to trace around the bolt holes from the old blade onto the new one, thereby duplicating the precise hole pattern. As a general guideline, aim to have the new blade protrude from the plow approximately the same thickness as the original blade served as the cutting edge. However, this suggestion may vary based on individual preferences and manufacturer recommendations.

Drilling Holes on the New Blade Following the marked outline, drill holes through the new blade according to the traced bolt pattern. Take care to ensure the holes are drilled straight and aligned accurately to guarantee a secure fit.

Securing the New Blade With the new blade prepared, position it beneath the old blade. The old blade now acts as a temporary support layer to help stabilize the new blade during installation. Alternatively, large washers can serve as placeholders to provide equivalent support. Start threading the bolts through the holes in the new blade and into the plow frame, securing them in place.

Extending the Life of the Blade Over time, as the new blade experiences wear from clearing snow, you have the option to extend its service life. Simply flip the blade upside down to expose the unused side as the new cutting edge. If necessary, re-drill the bolt pattern to accommodate the new position, allowing the wear strip to move downward. This process ensures efficient and continuous usage of the blade until it eventually requires replacement.

previous

previous

Product inquiry