Product Display

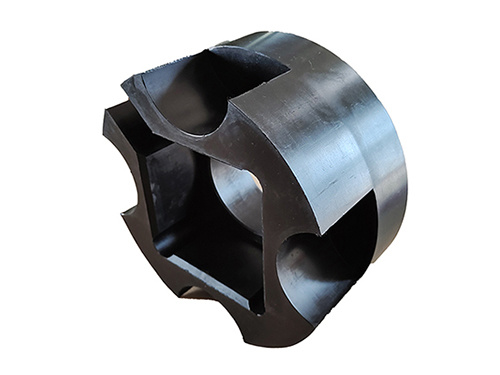

Polyurethane Doffer For Cotton Picker

Polyurethane is the ideal material choice for polyurethane doffers used in cotton picker and cotton sheller due to its superior abrasion-resistant properties. PEPSEN manufactures top-grade polyurethane doffers that excel within this industry niche. The cotton picker has been strategically conceived to augment your cotton field's overall productivity capacity.

Features & Advantages:

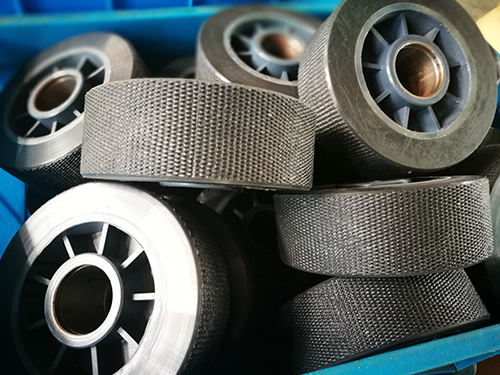

• Branded polyurethane raw materials are used to make doffer which is casted by advanced casting equipment.

•High grade steel plate guarantees superior strength and rigidity while maintaining excellent elasticity, thereby preventing any deformation issues during its operational lifecycle.

• To ensure a durable bond between the polyurethane and steel components, high-performance bonding agents are employed, guaranteeing a sturdy structure without the risk of delamination or separation.

•Packaging Industry: From box forming machines to labeling and sealing equipment, polyurethane coated idler rollers offer the right amount of grip and flexibility, ensuring that packaging materials aren't damaged during production.

• The doffer includes precision thickness steel structure, which perfectly matches the doffer disk.

Why Polyurethane?

Polyurethane’s non-marking and anti-static qualities contribute to maintaining the quality of harvested cotton by minimizing fiber entanglement and dust accumulation. It also offers resistance to a wide range of chemicals and environmental factors commonly encountered in agricultural settings, which extends the service life of the doffers significantly. Moreover, polyurethane's remarkable combination of strength, elasticity, and durability, coupled with its capacity for customization, renders it the most suitable and practical application for the production of high-quality polyurethane doffers in the demanding field of cotton harvesting and processing.

Customized Durometer & Formulation

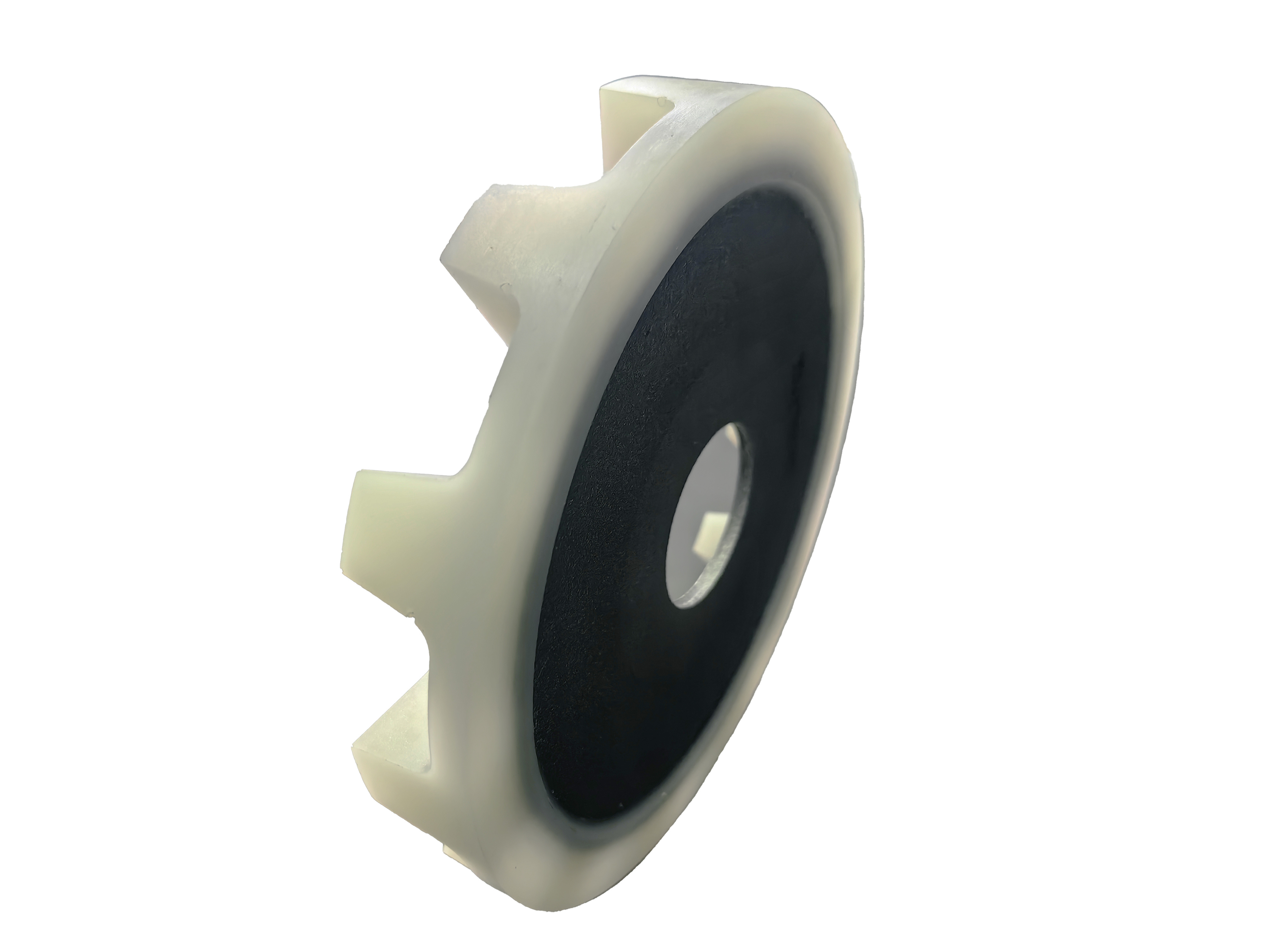

The durometer and formulation of polyurethane doffers are pivotal attributes that can be meticulously customized to meet the exacting demands of various cotton harvesting and processing environments. The durometer, which is a quantitative measure of hardness or softness, plays a critical role in determining the durability, abrasion resistance, and adaptability of the doffer pad.

By customizing the durometer, we ensure that each polyurethane doffer offers the perfect balance between stiffness for effective stripping of seed cotton from spindles and flexibility to prevent undue stress on the machinery or damage to the delicate fibers. This customization allows our clients to choose a hardness level that aligns with their specific cotton picker model, usage conditions, and the type of cotton being harvested.

In addition to durometer adjustments, we also specialize in formulating unique polyurethane blends tailored to address distinct operational challenges. Our expert team carefully selects and combines raw materials to engineer a polyurethane compound with enhanced properties such as improved wear resistance, tear strength, elasticity, and resilience against chemical exposure and extreme temperatures.

Our commitment to customization doesn't just stop at the physical properties; it extends to the chemical composition of the polyurethane itself. By leveraging advanced technology and deep industry knowledge, we create formulations that guarantee longevity, optimal performance, and cost-effectiveness over the lifespan of the doffer. Ultimately, this personalized approach ensures that the polyurethane doffers not only maximize the efficiency of cotton picking operations but also contribute significantly to the overall health and productivity of the cotton field.

previous

next

previous

next

Product inquiry