Product Display

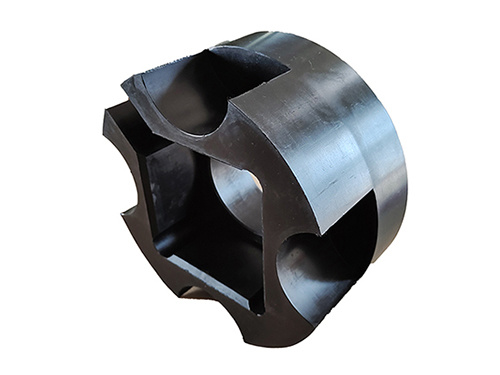

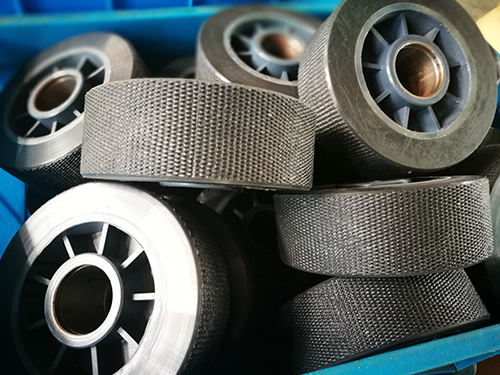

Urethane Cups and Discs For Pipeline Pigs

Urethane cups and discs are essential components of pipeline pigs, playing a crucial role in maintaining the integrity and efficient operation of oil, gas, and other fluid transportation systems. Specifically designed and manufactured for pipeline pigging applications, these urethane elements provide exceptional wear resistance, sealing capabilities, and adaptability to varying pipeline conditions. Shanghai Pepsen has been manufacturing cast polyurethane cups and discs for pipleine pigs in China since 2004.

Kinds Of Polyurethane Cups and Discs

Standard Cup

Conical Cup

Scraper Cup

Drive Cups

Standard Discs

Squeegee Discs

Multi-dimensional Cup&discs

Features & Advantages Of Polyurethane Cups and Discs For Pipeline Pigs

Superior Material Quality: Polyurethane cups and discs used in pipeline pigs are manufactured from premium-grade polyurethane elastomer, renowned for its resilience, durability, and chemical resistance. This ensures they can withstand the rigors of various pipeline cleaning and maintenance operations, while maintaining their structural integrity over time.

Efficient Liquid Removal: Designed with precision-engineered geometries, these cups and discs effectively scrape, scrape, and displace liquids, debris, and other contaminants from the pipeline walls. They excel in removing water, wax, scale, and other deposits, ensuring optimal flow capacity and minimizing the risk of corrosion or blockages.

Customizable Durometers: Available in a wide range of durometer hardness options, polyurethane cups and discs can be tailored to suit specific pipeline conditions and cleaning objectives. Softer durometers offer greater conformability to irregularities in the pipe wall, while harder durometers provide increased wear resistance for more abrasive environments.

One-Piece Construction: The one-piece solid polyurethane design eliminates the need for assembly, reducing potential failure points and simplifying pig deployment. This streamlined construction also contributes to improved reliability and longevity, as there are no joints or seams that could weaken or degrade over time.

Economical Solution: Despite their superior performance and durability, polyurethane cups and discs offer a cost-effective alternative to traditional materials like rubber or metal. Their long lifespan, reduced maintenance needs, and compatibility with multiple pipeline fluids make them a financially sound investment for pipeline operators.

Factors We Consider When We Design Polyurethane Cups and Discs

•Pipeline Geometry and Diameter: The design of PU cups and discs should closely match the internal diameter of the pipeline to achieve a tight, consistent seal. This may require customization based on pipeline size, ovality, and any existing anomalies or variations. Accurate measurements and tolerances are critical to prevent pig hang-ups or ineffective cleaning.

•Cleaning or Inspection Requirements: The type of pigging operation (e.g., cleaning, gauging, inspecting, or batching) will dictate the design features and material properties of the cups and discs. For instance, cleaning pigs may require more aggressive scraping or wiping elements, while intelligent pigs for inspection may necessitate specialized sensors or data acquisition systems integrated into the cup or disc design.

•Flow Conditions and Speed: The design must accommodate the expected flow rates, pressure differentials, and fluid velocities within the pipeline. This includes selecting PU materials with sufficient strength, flexibility, and resistance to erosion under high-flow conditions, as well as designing cup and disc geometries that can effectively maintain their shape and function at varying speeds.

•Sealing Performance: PU cups and discs should provide an effective seal against the pipeline wall, preventing fluid bypass and ensuring efficient cleaning or inspection. Factors such as cup profile (e.g., full-bodied, segmented, or foam-filled), disc stiffness, and surface finish should be optimized to create a strong, yet adaptable seal that can accommodate pipeline irregularities without causing excessive friction or damage.

Product inquiry