Product Display

Urethane Lined Hopper-Polyurethane Hopper Liners

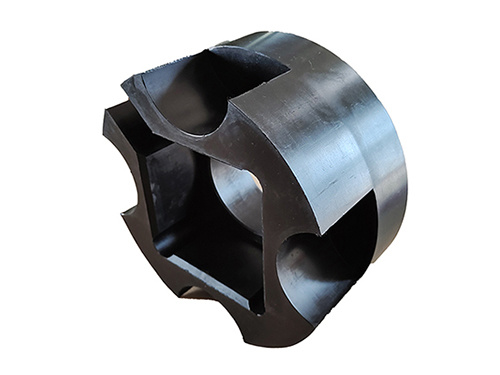

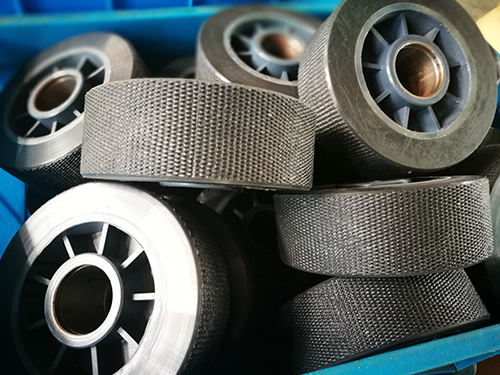

Shanghai Pepsen has been providing urethane lining hopper and polyurethane hopper liners since 2004 in China by using customized molds, formulations and processing techniques. Hopper bins, serving as substantial repositories for bulk materials or functioning as the initial receptacles in grain handling systems, significantly benefit from the implementation of urethane lining.

The Factors We Consider When We Design

1. The top of the hopper adopts the flange form to ensure rigidity, and 6 lifting lugs are welded on the outside of the flange used to fix the hopper with the sling.

2. In order to ensure that the polyurethane hopper in the temperature of -40℃ as far as possible not to shrink deformation, and have the rigidity and impact resistance, a 3mm thick screen with a 10mm aperture is embedded inside.

Advantages of Urethane Lined Hopper

•Mitigating wall friction during loading and unloading of light corrosive chemicals and grain commodities

•Curbing wall degradation due to abrasive wear

•Providing robust corrosion protection

•Noise abatement

Working Environment Of Urethane Lined Hopper

1. Seaport environment: Polyurethane hopper is used for port material transportation, and the port is located in the ocean or the bay. Nearby, the humidity in the air is usually higher. Marine moisture in port environment and perennial presence. Humid climate can lead to high air humidity, the relative humidity is often more than 70% or higher. Due to the high humidity and salinity of the Marine environment, port facilities and equipment are vulnerable to corrosion. The ambient temperature is lower: -40℃-40℃.

2. Material type: mainly transport potassium, chloride, ammonia and phosphorus specific gravity: 1.0T/m³, urea specific gravity: 0.75T/m³. The product density is low, but it has a certain corrosiveness.

Product inquiry