Product Display

Polyurethane Sheets With Expanded Metal Mesh

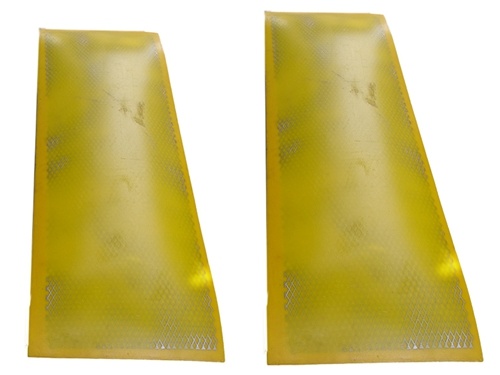

Shanghai Pepsen has been providing expanded metal mesh polyurethane sheet since 2004 in China by using customized molds, formulations and processing techniques. Polyurethane sheets reinforced with expanded metal mesh offer a unique combination of strength, durability, and versatility, making them a preferred choice for applications where enhanced mechanical properties and lightweight construction are essential.

How Does This Structure Be manufactured?

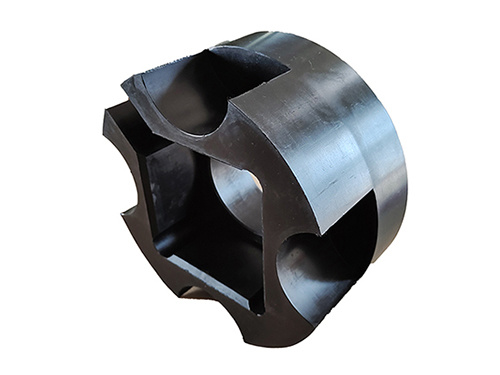

Polyurethane sheets reinforced with expanded metal mesh represent a hybrid composite material that combines the inherent benefits of both polyurethane and expanded metal. These sheets are characterized by a homogeneous layer of polyurethane, known for its excellent physical properties such as durability, resilience, and resistance to wear, tear, and impact, which is bonded to a layer of expanded metal mesh. The mesh, typically made from corrosion-resistant metals like stainless steel or aluminum, adds structural reinforcement, enhanced dimensional stability, and improved mechanical strength to the otherwise flexible polyurethane sheet.

The expanded metal mesh is created by slitting and stretching a metal sheet, forming a regular pattern of diamond-shaped or hexagonal openings. This process increases the surface area and creates a lightweight yet strong lattice structure that provides several advantages when integrated with polyurethane.

Applications:

Polyurethane sheets with expanded metal mesh find applications across various industries, including mining, construction, agriculture, food processing, and automotive. Common uses include:

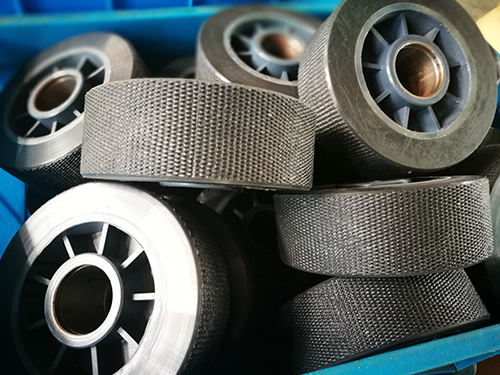

•Conveyor belt covers and liners

•Chute and hopper liners

•Protective coatings for equipment and structures

•Wear-resistant flooring and walkways

•Sound-absorbing panels and barriers

•Anti-slip surfaces

•Screen and filter media

Advantages Of Expanded Metal Mesh PU Sheet

Combined Strength and Flexibility: Expanded metal mesh PU sheets marry the exceptional strength and rigidity of the metal mesh with the inherent flexibility and resilience of polyurethane. This unique combination allows the material to withstand heavy loads, resist deformation, and maintain its shape while still accommodating bending or forming to fit complex geometries.

Enhanced Durability: The addition of the metal mesh significantly improves the wear resistance and overall durability of the polyurethane sheet. It protects the PU surface from abrasive forces, impact damage, and mechanical stress, prolonging the service life of the material in harsh operating environments.

Weight Reduction: Despite the reinforcement provided by the metal mesh, these sheets remain relatively lightweight due to the open, lattice-like structure of the mesh. This lightweight characteristic makes them suitable for applications where weight optimization is crucial without compromising on strength and durability.

Improved Thermal and Chemical Stability: The presence of the metal mesh can enhance the thermal conductivity and chemical resistance of the PU sheet, making it more suitable for applications involving exposure to high temperatures, aggressive chemicals, or corrosive environments.

Ease of Installation and Maintenance: The rigidity provided by the metal mesh can simplify installation, as the material can maintain its shape during handling and fastening. Additionally, the enhanced durability and wear resistance often result in reduced maintenance needs and extended service intervals.

Sound Absorption and Vibration Dampening: The combination of the porous metal mesh and the sound-absorptive nature of polyurethane can lead to improved acoustic properties, making these sheets suitable for applications requiring noise reduction or vibration isolation.

previous

previous

Product inquiry