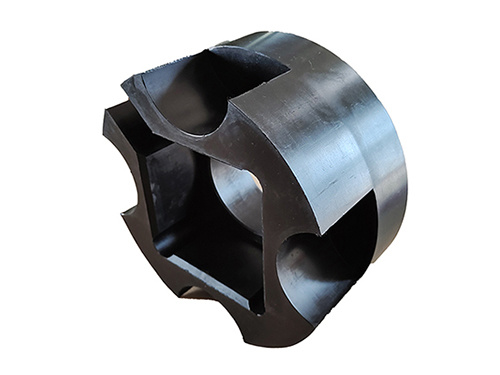

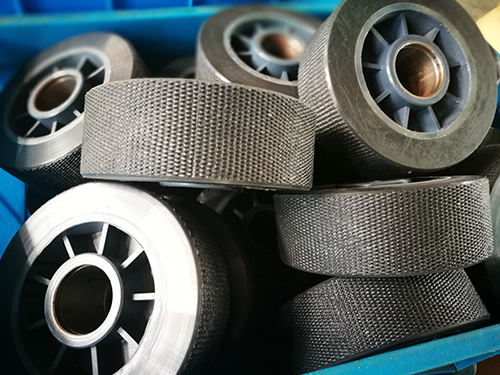

Product Display

VULKOLLAN® Polyurethane Friction Drive Wheel For Monorail Transport Systems

Shanghai Pepsen is the leading manufacturer of polyurethane friction drive wheels for suspended monorail transport systems in China. Polyurethane monorail wheel is widely used on transportation equipment for coal mine. Polyurethane materials have advantages over traditional cast steel or other materials in terms of service life and operating efficiency.

High Performance Polyurethane Tread

The working condition of monorail is harsh. The wheels are often exposed to heat, water, dust and minerals. They also need to bear high load, dynamic wear and shear force when monorail transport systems work.

To meet these needs, PEPSEN offers high-performance polyurethane tread materials such as VULKOLLAN® and PEPSEN NDI based polyurethane material. Both of them have been approved by many applications and customers .In most applications, PEPSEN NDI based polyurethane exceeds while it is less expensive than VULKOLLAN®.

Why Choose PEPSEN Polyurethane Drive Wheels?

•Both Vulkollan material and PEPSEN NDI based polyurethane material available

•Automatic production process and casting machine .

•Strict process control from wheel core treatment, applying bonding agent, casting process and post curing.

•Temperature and humidity control during production process

Benefits of Polyurethane Friction Drive Wheel

•Excellent abrasion resistance

•High load capacity and low heat build-up

•Good dynamic performance and impact resistance.

•Good friction and traction

•Heat resistance

•Oil and chemical resistance

•Water resistance

•Flame retardant and Anti-static

previous

previous

Product inquiry