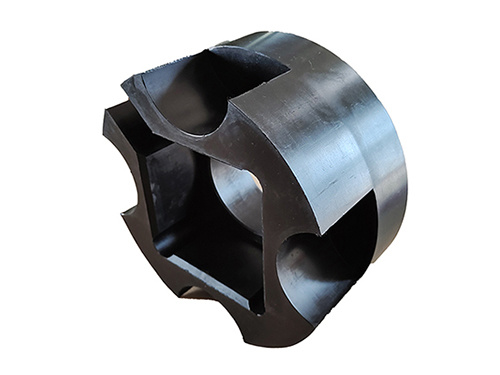

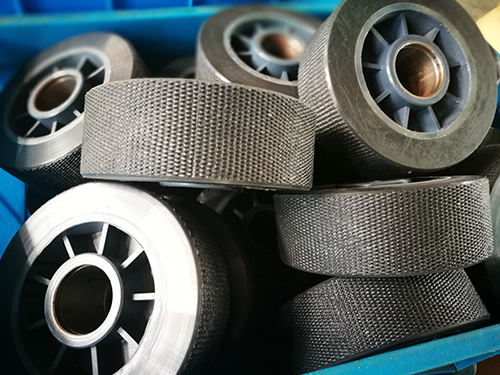

Product Display

Polyurethane Coated Bearing (Casting, not injection)

Shanghai Pepsen has been producing customized polyurethane coated bearing since 2004 in China. Polyurethane coated bearings are more and more widely used in many industries such as automation, logistics and transportation. They are mainly used to avoid damage to stuff and reduce noise.

Why Choose PEPSEN Polyurethane Coated Bearing?

•Strong bonding

•Special mold design to avoid damage to bearings

•Protection sealing cap/fixture to prevent sand going into bearings during sandblasting process

•Temperature and humidity control during production process

Benefits of Polyurethane Coated Bearing

•Excellent Wear resistance

•Impact resistance, not easy to crack

•Shock absorption and sound absorption

•Wear resistance, oil resistance, good corrosion resistance, can be used in harsh environments

•Anti-static polyurethane covered bearing is available

•Special outer shape can reduce the contact area with the work piece

Precautions of Using Polyurethane Covered Bearing

•Should be stored away from light and moisture

•Size polyurethane will change with the temperature, but the change is not large, and placed at room temperature for a few hours can be restored to the original size.

•Tolerance of hardness can be +/-5 A or +/-3A , gauged under room temperature

Product inquiry