Product Display

Polyurethane U-Grooved Wheels

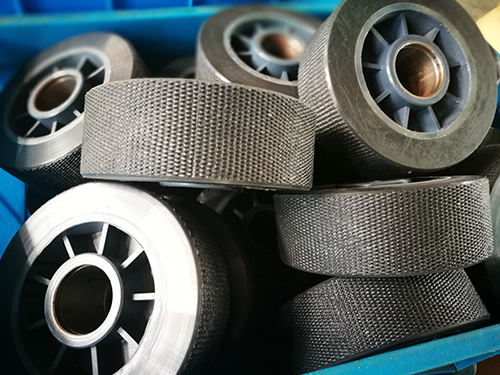

Shanghai Pepsen has been supplying quality polyurethane U-Grooved wheels since 2004, which can be used as idler or drive wheels. They can come with bearings or with a straight bore. The U-Groove design of these wheels is a popular choice for many applications that require high traction and durability. They can be produced based on technical drawings or from an existing sample.

U-Groove Design &Polyurethane Combine

The U-Groove design improves durability and wear resistance. The polyurethane material used in these wheels is exceptionally durable and resistant to harsh conditions. The U-Groove design reduces wear by distributing the load evenly across the wheel's surface, reducing stress concentrations and wear patterns.

Benefits Of Polyurethane U-Grooved Wheels

The U-Groove design offers several advantages. Firstly, it provides better traction on various surfaces, enabling the wheel to handle rough terrain and uneven surfaces effectively. The U-shaped groove allows the wheel to bite into the ground, providing a secure grip and preventing slipping or skidding. Secondly, the U-Groove design allows for easy cleaning and maintenance. The U-shaped groove traps dirt and debris, keeping it away from the wheel's bearing surfaces. This helps to prevent premature wear and extends the life of the wheel. The groove can also be used to channel water away from the wheel, reducing corrosion and rusting.

Can Be Molded or Machined

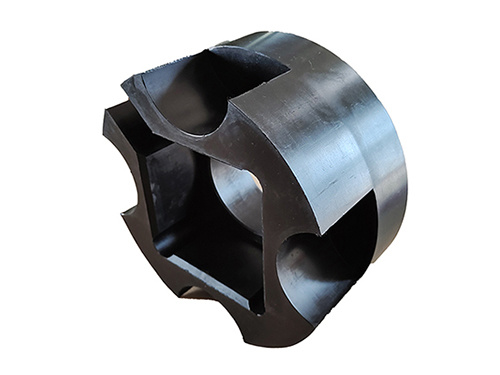

Molding is a common method used to create U-Grooved wheels. It involves pouring the polyurethane material into a mold that has the desired shape and size of the wheel. The material is then cured, or allowed to set, and the resulting wheel has the desired U-Groove design. Molding allows for the production of large quantities of wheels with consistent quality and geometry.

Machining is another option for manufacturing U-Grooved wheels. This process involves using machine tools to cut or shape the wheel from a solid block of polyurethane material. Machining offers more flexibility in terms of geometry and allows for the production of custom-shaped wheels that may not be feasible through molding. However, it is generally more time-consuming and expensive compared to molding.

If you have a specific application or requirement for polyurethane U-Grooved wheels, it is recommended to consult with PEPSEN representatives to discuss the best manufacturing method and material selection based on your specific needs and budget.

Product inquiry