Product Display

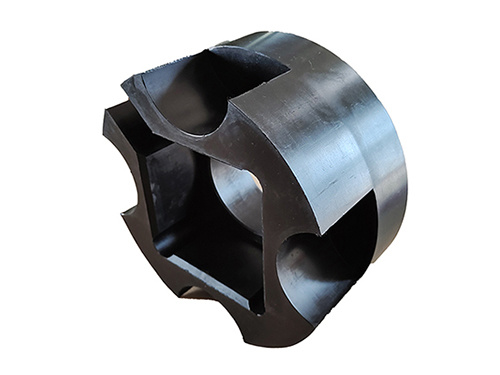

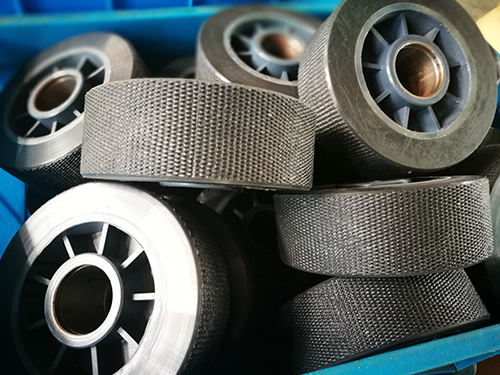

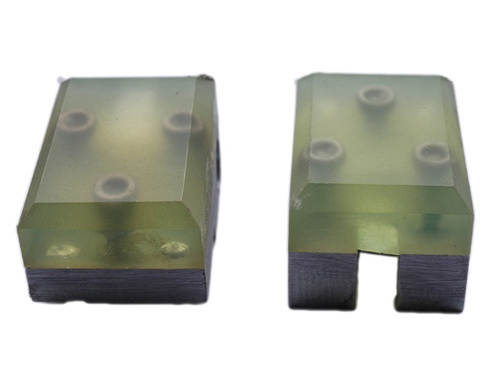

Custom Molded Polyurethane Bumpers

Shanghai Pepsen can work closely with customers in China and abroad to design and produce polyurethane bumpers with tailored features for optimal performance and protection in their intended use cases. Custom molded polyurethane bumpers offer durability, excellent performance, and the ability to meet specific application requirements.

Types of Polyurethane Bumpers

Bumper Pad

Bump Stop

Bumpers With Metal Insert

Bumpers With Metal Plate

Thread Round Bumper

Dual Hardness bumpers

Applications of Custom Molded Polyurethane Bumpers

1. Automotive Industry: Polyurethane bumpers are commonly used in the automotive industry for bumpers, side skirts, and fender applications. They provide impact resistance, protect against minor collisions, and aid in reducing vehicle damage.

2. Industrial Equipment: Polyurethane bumpers are used in various industrial applications, such as in material handling equipment, conveyor systems, and machinery. They protect surfaces, reduce noise and vibrations, and enhance safety.

3. Electronics and Appliances: Custom molded polyurethane bumpers are employed in electronic devices and appliances as protective buffers. They can prevent damage from accidental drops or impacts.

4. Furniture and Cabinet Making: Polyurethane bumpers are used in furniture and cabinet manufacturing to prevent damage, minimize noise, and provide stability when closing or sliding doors and drawers.

5. Sports Equipment: Some sports equipment, such as gym machines, treadmills, and weights, use polyurethane bumpers to absorb impact, reduce noise, and enhance safety.

Features of Polyurethane Bumpers

1. Impact Resistant: Polyurethane bumpers exhibit excellent impact resistance compared to traditional materials like rubber or plastic. They can absorb and disperse energy from impacts, reducing the potential for damage or wear.

3. Durometer (Hardness) Options: Polyurethane bumpers can be manufactured with different durometer hardness options, allowing for customization based on required flexibility or rigidity. This enables precise tuning of the bumper's performance characteristics.

2. Customizable Shapes and Sizes: PEPSEN can mold polyurethane bumpers into a wide range of shapes, sizes, and designs according to specific application needs. This customization ensures an optimal fit and performance.

4. Abrasion and Wear Resistance: Polyurethane bumpers are highly resistant to abrasion and wear, making them suitable for applications where continuous contact or rubbing occurs. They can withstand harsh conditions without degradation.

5. Vibration Dampening: These bumpers can isolate or dampen vibrations, providing cushioning and reducing noise levels in machinery or equipment. This feature helps minimize wear, noise transmission, and improves overall equipment performance.

previous

next

previous

next

Product inquiry