Product Display

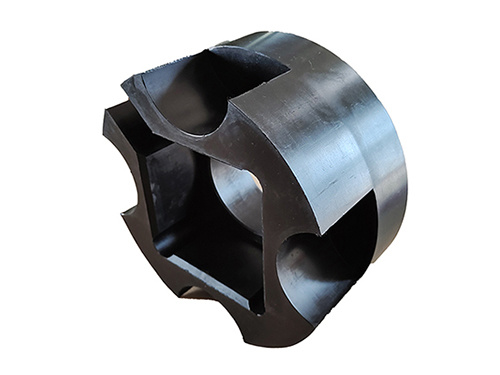

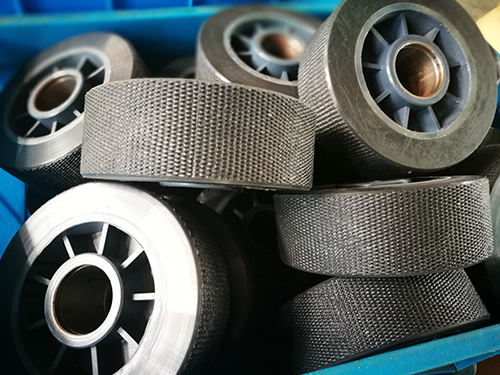

Custom Molded Polyurethane- PUR Damper

By selecting polyurethane as a material for vibration damping components, you can take advantage of its viscoelastic properties to dissipate energy and reduce the negative effects of vibration. Proper design considerations, such as minimizing heat build-up, contribute to optimal performance and longevity of these components.

With years of knowledge and experience of designing polyurethane vibration damping components, Shanghai Pepsen can help customers not only fulfill vibration damping, but also vibration isolation.

Types of Polyurethane damper

Vibration damper

Hydraulic Rock Breaker Damper

Exhaust pipe /hanger damper

Machinery mounts, feet, pads, and bumpers

Damper pad

Polyurethane sound damper

Heat Build-up Considerations

When designing polyurethane components for vibration damping, it's crucial to consider heat build-up. Vibration with high frequency and/or large amplitude can generate more heat within the polyurethane material. Designing for lower strains and better heat dissipation can minimize heat build-up and avoid potential heat-related issues.

High-Load Applications and Medium to High-Frequency Vibration

Polyurethane is particularly well-suited for high-load applications that experience medium to high-frequency vibration. Its properties allow it to effectively absorb and dissipate the energy generated by vibrations, contributing to improved machinery performance and reduced wear and tear.

previous

next

previous

next

Product inquiry