Product Display

Polyurethane Coil Spring Spacers-Urethane Lift Isolators

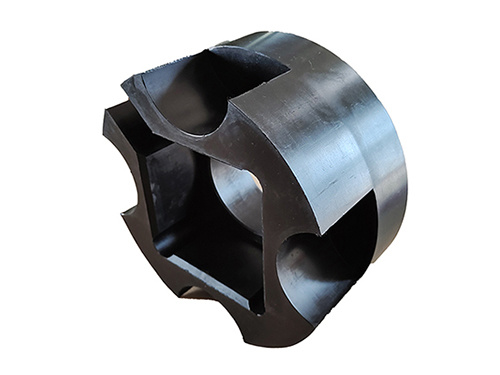

Shanghai Pepsen has been manufacturing custom cast molded urethane coil spring spacers in China since 2004. Polyurethane coil spring spacers are specialized components used in automotive suspension systems to modify or enhance the vehicle's ride height, handling characteristics, and load-carrying capacity. They consist of cylindrical or conical shaped polyurethane inserts that are placed between the coil springs and the spring seats or spring perches.

Why Polyurethane?

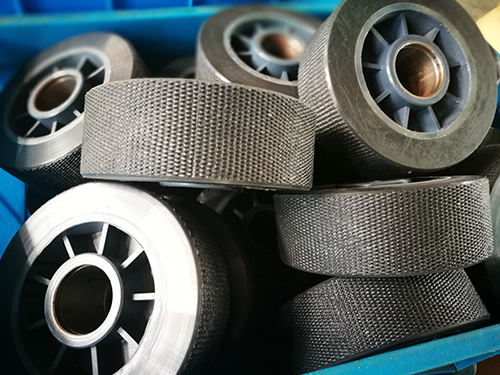

Made from high-quality, durable polyurethane, these spacers offer a combination of strength, resilience, and resistance to wear, compression set, and environmental factors such as oil, grease, and extreme temperatures. Polyurethane's inherent elasticity allows it to absorb and dissipate energy, contributing to improved ride comfort and reduced noise, vibration, and harshness (NVH) compared to rigid metal spacers.

Advanced Material Science

PEPSEN likely partners with reputable material suppliers or has in-house expertise to formulate custom polyurethane compounds optimized for coil spring spacer applications. These compounds may offer a balance of high tensile strength, excellent rebound properties, resistance to compression set, and durability in harsh environments. By selecting the right polyurethane formula, PEPSEN ensures that their spacers maintain their performance characteristics over time and under varying loads.

Precision Engineering and Design& Manufacturing Capabilities

PEPSEN likely employs experienced engineers who utilize advanced design tools and techniques, such as computer-aided design (CAD) and finite element analysis (FEA), to develop spacers with precise geometries and optimized stress distribution. This attention to detail ensures that the spacers fit correctly, function efficiently within the suspension system, and withstand the rigors of daily use without degrading or causing premature wear on adjacent components.

PEPSEN likely operates modern manufacturing facilities equipped with state-of-the-art machinery for polyurethane processing. These facilities enable efficient, high-volume production while maintaining tight tolerances and consistent material properties. Additionally, PEPSEN may have in-house tooling capabilities, allowing for quick prototyping and customization to meet unique customer requirements.

Product inquiry