Product Display

Polyurethane Rubber Conveyor Rollers

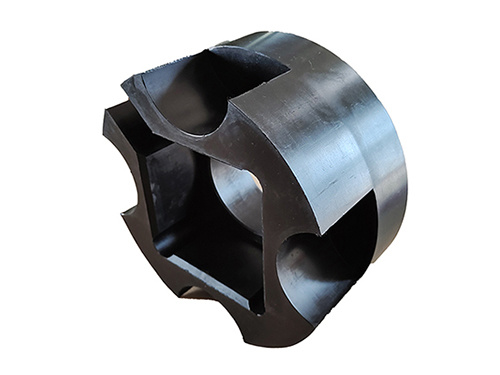

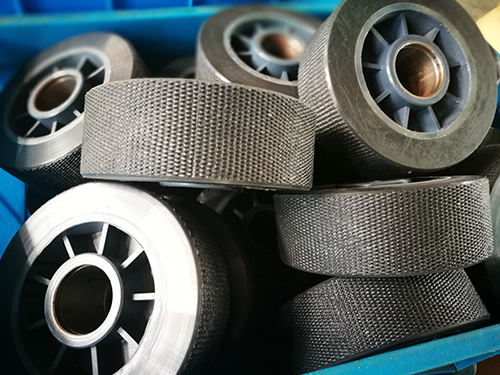

Shanghai Pepsen has been manufacturing polyurethane rubber conveyor rollers in China since 2004. Polyurethane Rubber Conveyor Rollers are specialized rollers used in conveyor systems that consist of a metal core, typically steel, covered by a layer of polyurethane rubber. This combination creates a hybrid roller that offers a blend of the strength and structural integrity of metal with the advantageous properties of polyurethane.

The Function of Polyurethane Rubber Conveyor Rollers

•Support and Movement: Polyurethane Conveyor Rollers are positioned beneath a conveyor belt or chain to provide support and maintain the desired shape and tension of the belt. As the main drive mechanism (usually a motor-powered pulley) turns, it moves the conveyor belt through a sequence of rotating rollers.

•Friction and Grip: The polyurethane coating on the roller surface interacts with the conveyor belt, creating the necessary friction to grip and propel the belt forward. This grip reduces slippage and ensures that the conveyed materials move steadily and uniformly along the conveyor path.

•Load Distribution and Wear Resistance: The hard-wearing nature of polyurethane reduces the impact of concentrated loads on the belt and distributes the force evenly. The durability of the polyurethane material minimizes wear caused by repeated contact with conveyed materials, particularly in cases where abrasion or impact is significant.

•Shock Absorption and Noise Reduction: The elastomeric properties of polyurethane help absorb shock and vibrations, which contributes to a quieter and smoother operation. This can be particularly important in sensitive environments where noise control is essential or in applications where jolts and jerks could damage products or equipment.

•Alignment and Tracking: Properly spaced and adjusted polyurethane conveyor rollers also help maintain the conveyor belt's alignment and tracking, ensuring that it stays centered on the conveyor frame and doesn't drift off course.

Feature & Advantages:

We specialize in offering polyurethane-coated idler rollers that are renowned for their exceptional wear resistance, noise reduction capabilities, and ability to handle a wide variety of loads and speeds. The polyurethane coating adheres firmly to a sturdy metal core, ensuring that our rollers can withstand the harshest operating conditions while maintaining smooth, consistent motion on your conveyor belts.

Searching For Polyurethane Idler Rollers For Your Material Handling&Conveyor Applications?

If you're searching for idler rollers for your material handling and conveyor applications, look no further! Our premium range of idler rollers are designed and engineered to provide outstanding performance, durability, and reliability across a multitude of industrial settings. Our idler rollers come in a variety of sizes, diameters, lengths, and hardness ratings to suit your specific application needs. Whether you require low-friction rollers for delicate items or heavy-duty rollers for abrasive materials, we've got you covered. Additionally, our rollers are built to last, significantly reducing maintenance and replacement costs over time. For those working in environments with stringent hygiene standards, we also provide FDA-compliant and easily cleanable polyurethane options ideal for food processing, pharmaceuticals, and similar industries. Our team of experts can assist you in selecting the perfect idler rollers for your system, taking into account your load requirements, conveyor configuration, and any unique challenges presented by your application. We pride ourselves on delivering customized solutions that not only meet but exceed your expectations, ultimately driving up productivity and efficiency in your material handling processes. Contact us today to discuss your idler roller requirements and discover how our high-quality products can enhance your conveyor system's performance.

previous

previous

Product inquiry