Product Display

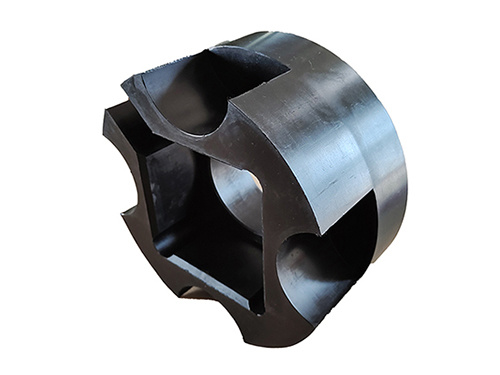

Polyurethane Zero-Crush Wheel/No Crush Wheel

Just like polyurethane is also called urethane or PU. Zero-Crush Wheel is also known as no crush wheels/rollers, bottle spacer wheels, PU sun wheels, hold-down wheels, feed rollers and soft touch wheels/rollers. They are all made from cast polyurethane, which are widely used in many industries and applications. These two things can be achieve through adjusting urethane formulas and applying the right design. The standard No Crush Urethane Roller's durometer lies between 40A and 75D, that's the softness of a rubber band to the hardness of a leather belt.

Benefits Of No Crush Wheel

• Holes and spaces enable no crush rollers with the flexibility to move the product along without marring it.

• Shock absorption and cushioning.

• Reduce build-up heat under high speed

• Spokes can reduce flute deformation and fatigue.

• No crush rollers are available in any color size or shape.

The Main Applications Include:

• Corrugated cardboard processing

• Bottle spacing conveyor line,

• Printing

• Packing machine

• Product labeling

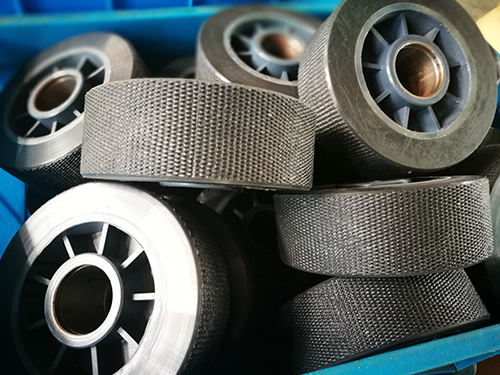

Can be all polyurethane or bonded to metal insert

No crush roller can be all polyurethane or be molded on a metal insert/core/hub. When a no crush roller is worn down, we can strip off the old urethane, then recoated with new polyurethane.

When applications require the material to be driven or pulled, an hub will be required, so it can be used as driven roller. These wheels/rollers usually have a set screw on the hub. The screw ensures the roller locked on the shaft and in this case they are used a drive roller or called hubbed zero crush wheel.

When it is used as idler wheels, zero crush wheels can also have machined cores with bearings pressed in the center.

previous

previous

Product inquiry