Product Display

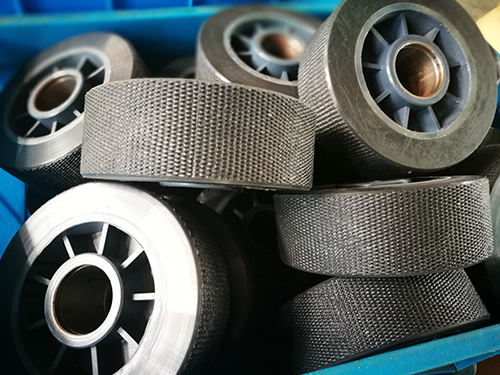

Shanghai Pepsen started main business from recovering/ refurbishing old polyurethane rollers for local clients in 2004. Now it becomes one of our main business. With the quick development in past twenty years, we accumulated both experience and advanced equipment. We are capable of casting and machining big diameter and long polyurethane rollers, machining and grinding rollers by CNC.

Advanced casting and mixing facilities assures inner quality

Taking the advantages of advanced polyurethane casting machines and state-of-art mixer, these ensure the uniform distribution of ingredients and the consistent quality of the polyurethane material. This ensures that the physical properties, such as tensile strength, flexibility, and durability, are optimized in every roller we produce.

These facilities allow for more precise control over the casting process for polyurethane roller, leading to consistent and reliable quality. We are able to guarantee the inner quality of our polyurethane rollers. This not only enhances their performance but also extends their lifespan, reducing the need for premature replacements.

Little or no tooling cost.

Due to the flexibility of the polyurethane material, easy molds can be used for low volume production, this can reduce mold costs greatly. Shanghai Pepsen has hundreds of existing easy molds in stock with different diameter and length.

Additionally, since the shape and specifications of polyurethane rollers can be flexibly customized and machined by CNC, it also reduces the need for extra precision mold production for different specifications.

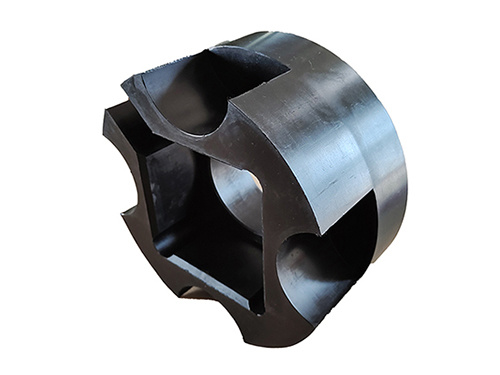

In-house CNC and 10 meters long lathe available

The CNC machine has enabled us to provide precision polyurethane rollers. Through advanced computer programming, we can precisely control the path and speed of cutting tools, enabling the production of polyurethane rollers with complex shapes and fine features. This technology not only improves production efficiency, but also greatly reduces human error, ensuring product consistency and reliability.

The 10-meter long lathe provides us with the capability to handle large polyurethane rollers. Its extra-long worktable can accommodate large-sized rollers, enabling us to complete the processing of the entire roller in one single operation, without the need for segmented processing. This not only saves time and cost, but also ensures the concentricity and stability of the rollers.

next

next

Product inquiry