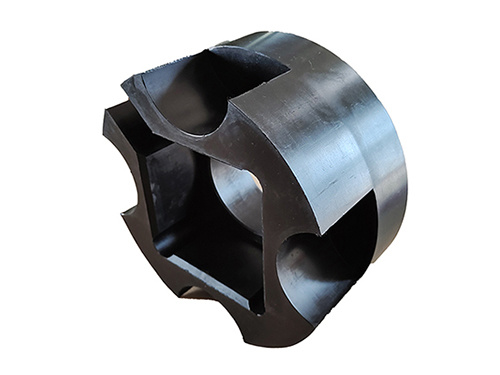

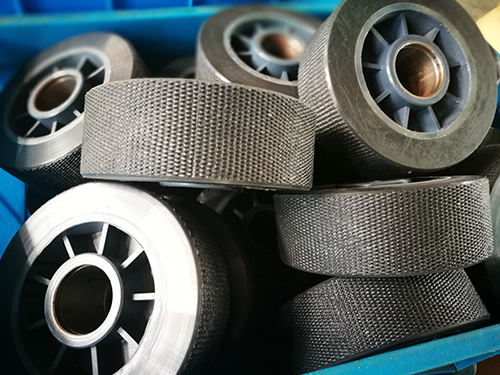

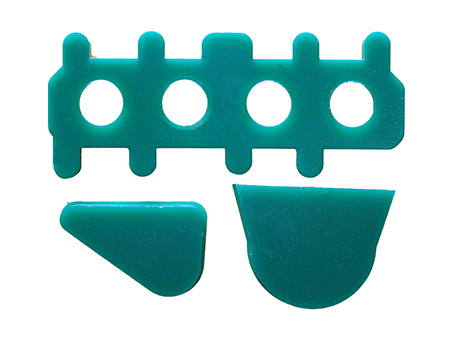

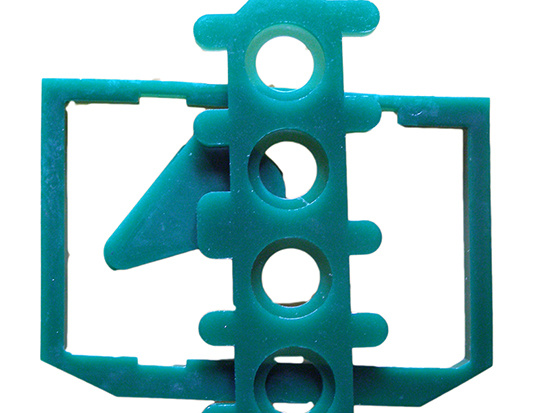

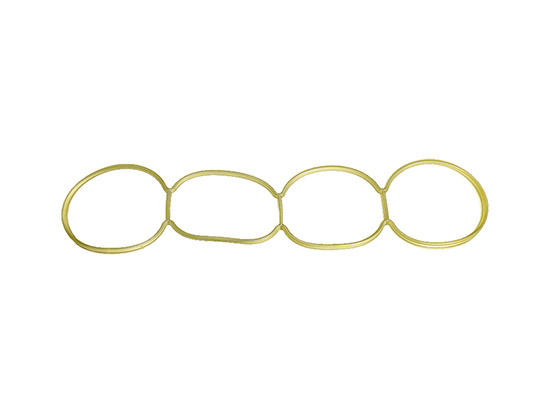

Product Display

Polyurethane Leak Testing Gasket/Seal

PEPSEN specializes developing and manufacturing polyurethane leak test gasket. It is a high-performance sealing solution designed for leak testing applications across various industries. These gaskets are widely used in automotive, aerospace, chemical, and electronics sectors, where reliable and precise leak detection is crucial.

What is a Leak Test?

Leak tests are essential quality control procedures used to verify the seal integrity of products, ensuring they meet specific regulatory and performance standards. This testing technique is widely applied to various objects that are susceptible to gas or liquid leaks, such as batteries, motors, pumps, medical bags, and more. The primary purpose of leak testing is to ensure that these products are free from any leaks that could compromise their functionality, safety, and overall performance.

Why Choose Polyurethane?

•Chemical Resistance: Resistant to a wide range of chemicals, including oils, greases, and many solvents.

•Abrasion and Wear Resistance: Highly durable and can withstand repeated use and high-pressure conditions.

•Temperature Range: Performs well across a broad temperature range, from very low to relatively high temperatures.

•Flexibility and Resilience: Highly elastic and flexible, conforming to irregular surfaces and providing a tight seal.

•Customizability: Can be formulated to different hardness levels and molded into various shapes and sizes.

•Sealing Performance: Provides reliable airtight and watertight seals, crucial for accurate leak testing.

How can PEPSEN Ensure the Reliability of Leak Test Gaskets?

•High-Quality Raw Materials: Use only high-grade polyurethane and other materials from reputable suppliers.

•In-Process Inspections: Conduct regular inspections at various stages of the manufacturing process to catch and correct any defects early.

•Batch Testing: Perform batch testing to ensure that each lot of gaskets meets the required specifications such as hardness, dimension and surface finish.

•Feedback Loop: Establish a feedback loop with customers to gather insights on gasket performance and make continuous improvements.

Product inquiry