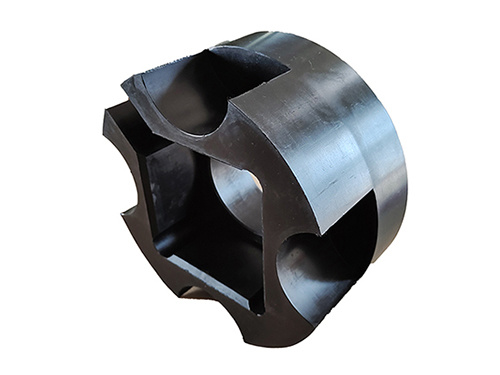

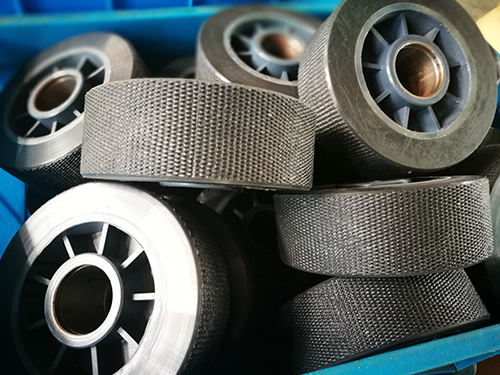

Product Display

High Performance Urethane Vulkollan Rollers

Shanghai Pepsen has been developing and manufacturing customized Vulkollan roller for many industries in China since 2004. They have been widely used in material handling, mining, mobile transport devices.

Vulkollan rollers are high-performance elastomeric products made from Vulkollan®, a material known for its exceptional strength and dynamic properties.

Benefits Of Vulkollan Rollers

• High Temperature Resistance up to around 125 °C, with only a reversible reduction in the elasticity modulus at high temperatures. This makes them suitable for use in a wide range of temperature environments, from cold storage facilities to high-temperature industrial processes.

• Low build-up heat under high speed and load

• High Load-Bearing Capacity

• Exceptional Wear Resistance

• Optimal Chemical Adhesion to Metal Surfaces

Material and Quality

The Vulkollan rollers from Shanghai Pepsen are crafted using top-notch Vulkollan polyurethane material. Vulkollan, a high-performance polyurethane developed by Bayer, is known for its exceptional properties. It provides these rollers with excellent abrasion resistance, ensuring that they can withstand prolonged use and heavy loads without significant wear and tear. This means that they maintain their performance and dimensional accuracy over an extended period, reducing the need for frequent replacements.

With a team of highly skilled engineers and technicians, Shanghai Pepsen has continuously strived to meet the diverse and specific requirements of different sectors. Their commitment to quality and innovation has enabled them to produce Vulkollan rollers that are not only durable and reliable but also tailored to the unique needs of each industry.

How to Select Vulkollan Rollers for Specific Applications?

1. Load Requirements

Weight-Bearing Capacity: In industrial conveyor systems used for transporting heavy or large components of mechanical equipment, high-load-bearing-capacity Vulkollan rollers should be selected.

Type of Load: Consider whether the load is static or dynamic. The rollers that carry materials moving frequently on an automated assembly line, in addition to bearing the static load of the materials themselves, they also need to handle the dynamic impact loads during frequent starts, stops, accelerations, and decelerations. Vulkollan rollers with excellent dynamic load performance, such as those with good elastic recovery ability to cope with impacts, should be selected.

2. Operating Speed and Frequency

Operating Speed: When operating at high speed, factors such as centrifugal force and heat generation of the rollers will affect their performance. High-quality Vulkollan rollers are designed to take these factors into account, having good dynamic balance and heat dissipation capabilities to ensure that they can roll smoothly without jittering or overheating at high speed.

Operating Frequency: In the application of elevator car rollers with frequent starts and stops,the operating frequency is high. For high-frequency operation scenarios, Vulkollan rollers with good abrasion resistance and long fatigue life should be selected so that they can maintain good performance during long-term and high-frequency operation without quickly suffering from severe wear or fatigue fracture.

previous

previous

Product inquiry