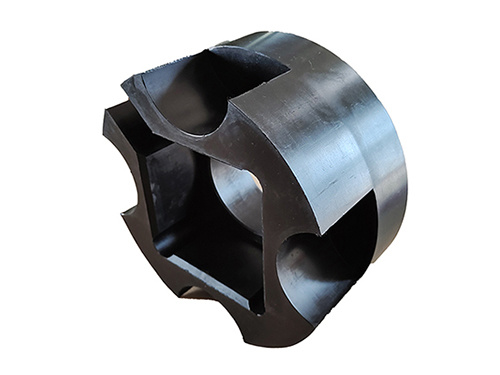

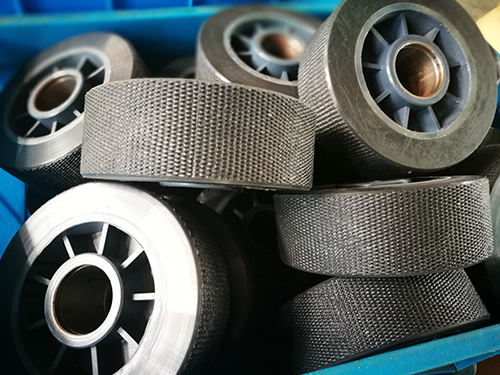

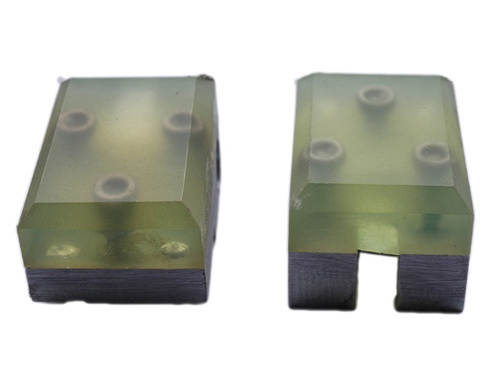

Product Display

Polyurethane Overmolding, Insert Molding

Polyurethane overmolding or insert molding is the process of overmolding polyurethane on insert made of metal, rubber or plastic. Shanghai Pepsen has been providing polyurethane overmolding service since 2004 in China by using customized molds, reliable formulations and bonding procedures.

By following strict process control procedures and testing of bonding strength, PEPSEN can guarantee high-quality bonding between polyurethane and inserts, providing strong and durable protection in various applications.

Surface treatment of inserts

Surface preparation and cleanliness throughout the entire process are the most vital factors in obtaining reliable adhesion of cast urethane elastomers to metal surfaces. The following guide lines are based on our experience with the most common causes of adhesion failure. Start with the metal as clean as possible. Remove as much grease, oil or other contamination as possible. Detergent washing to remove all residual grease and oil is desirable.

Sandblasting

Grit blast with clean sharp grit. Make sure there is no oil on the grit or in the compressed air. The blasted surface should have a uniform white appearance (so- called “white blast” appearance). Check for residual contamination of the metal on a separate test piece by placing a strip of masking tape on the surface and rubbing hard with a wooden handle of a knife or something similar.

Bonding&Casting

Apply bonding agent as soon as possible, but only within one hour. Carefully follow the instructions for pre-baking temperature, time, film thickness, drying, etc. Do not leave adhesive too long or tools that may be contaminated.

Ensure that the temperature of each part is accurate and consistent when pouring; Metal inserts must reach the required temperature. The difference in temperature will cause the polyurethane to shrink differently and destroy the bonding effect.

Testing

The finished adhesive can be tested for the adhesive effect. It is inevitable to sacrifice one or two products. The edge of the adhesive part is bent with the tip of the knife, or by any appropriate means, the polyurethane and the metal are peeled off. If a large amount of polyurethane is adhered to the metal, the adhesive strength is higher than that of similar materials.

previous

next

previous

next

Product inquiry